WELDING INSPECTION WITH PARTIALLY PRINTED FILM

Among the features that Viewtech can proudly include as standard in Optical Sorting Machines, the possibility of welding inspection when the top film is partially printed, occupies an important item.

We are talking about sorting machines for the automation of quality control in tray food packaging lines.

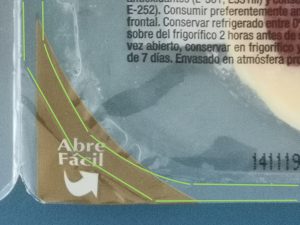

Often, for marketing reasons, the top film of the tray presents the print that partially covers the weld.

Many of our competitors have optical sorters which in these cases are NOT able to complete the welding inspection. In some cases they even require the areas where the top film is printed to be excluded from the inspection.

VT-Match, the software that manages Viewtech optical sorters, allows complete inspection of the weld. This is possible EVEN when the top film has the print that partially covers the welding area.

The flexibility of VT-Match allows to identify contaminations, residues of the packaged product, gas bubbles, leakages, on the whole area of the welding, even when the print overlaps partially or totally the welding itself.

It is precisely this specification that, on the Spanish market, has allowed Viewtech to outperform the most important of our competitors.

In July 2019 we were contacted by a company that packs sliced cold cuts in trays; this company had already purchased a sorting machine from our most famous competitor, but was not satisfied with the result.

After the presentation of the Viewtech VT2507 sorter machine, with which we demonstrated the real possibility of the complete welding inspection on trays with partially covering top film, we installed the first unit.

Since then, the progression has been significant and, over the next 9 months, we have installed 5 units.

Further details on Viewtech sorters are available on the pages of our official website. For immediate contact, simply fill in the form below.